Aluminum phosphating. In addition, the results of these studies have shown that guanidine nitrate possesses the qualities of having a high water solubility. Citation neededNeeds additional citationsIn addition to this, there is evidence that fluoride possesses antimicrobial and antifungal properties. These properties have been demonstrated. The grains should be refined, the phosphating film should be made uniform and dense, and the appearance of the phosphating film should be improved, are all suggestions that have been made. a method for the grinding of aluminum that makes use of solutions that are, respectively, alkaline and electrolytic in nature.

The alkaline grinding solution system was analyzed, and the results of comparing the effects of various additives on the grinding effect were presented. The results showed that some of the additives increased the grinding effect while others decreased it. According to the findings, some of the additives boosted the grinding effect, while others had the opposite effect and reduced it. According to the results of the tests, an excellent grinding effect can be accomplished by enhancing a solution of NaOH with the appropriate additives in the appropriate proportions. This was determined by the findings die casting services of the tests. This is something that can be done in order to get the effect that is desired. However, in order to take into consideration the unpredictability of the factors that were a part of the experiment, additional research is required. The production of aluminum and aluminum requires a process that involves the grinding of aluminum and aluminum in a mill with chemicals that are safe for the environment. This process takes place during the production phase.

The new chemical grinding technology that will be the primary focus of this project will have phosphoric acid and monosulfuric acid as its foundational components, respectively. This technology will have a minimal effect on the natural environment in the surrounding area. When it comes to the chemical grinding of aluminum, the primary functions that nitric acid serves are to prevent pitting corrosion and to improve grinding brightness. Nitric acid also improves the overall appearance of the ground aluminum. In addition to this, the appearance of the ground aluminum is enhanced as a whole by nitric acid. After the grinding has been completed, the addition of nitric acid is another factor that has the potential to contribute to the process producing a finer powder. A method that makes use of electrochemistry to strengthen the surface of aluminum and the alloys that aluminum is composed of in order to make them better able to withstand the effects of wear and tear on their surfaces.

In the following paragraphs, we will discuss the technology that is used to make ceramic-like amorphous composite conversion coatings, as well as their properties, shapes, chemical make-up, and structural make-up. The concentration of ceramic-like amorphous composite conversion coatings ranges from 0.5 to 3.0g/l. It is suggested that a stirring strength of between 0.0 g/l be used, that the peak current density be between 6 and 12 A/dm2, and that the concentration of Na2WO4 be between 0.0 g/l. These parameters should all be adhered to in order to achieve the best possible results. In addition to having a microhardness that ranges from 300 to 540 HV, the film possesses excellent resistance to corrosion. The microhardness of the film ranges from 300 to 540 HV. The microhardness of the film varies from 300 to 540 HV across its entire surface. The microhardness of the film's surface ranges from 300 to 540 HV consistently all the way across its entirety.

This neutral system has a good adaptability to aluminum alloys, and several different series of aluminum alloys, such as rust-proof aluminum and forged aluminum, can be used as films. The adaptability of this system to aluminum alloy die casting is very good. In addition to that, the adaptability of this neutral system to magnesium alloys is quite high. In addition to this, the neutral system exhibits a high degree of adaptability with regard to magnesium alloys. Case in point:Before the material can be applied, the surface of the material needs to be treated in order to make it more resistant to corrosion and to form a surface layer that is easy to combine with organic coatings. In addition, this step is necessary in order to make the surface of the material simpler to combine with organic coatings. This step absolutely needs to be finished before you can move on to applying the material. Before moving on to the next step, which is applying the material, this step must first be finished in its entirety.

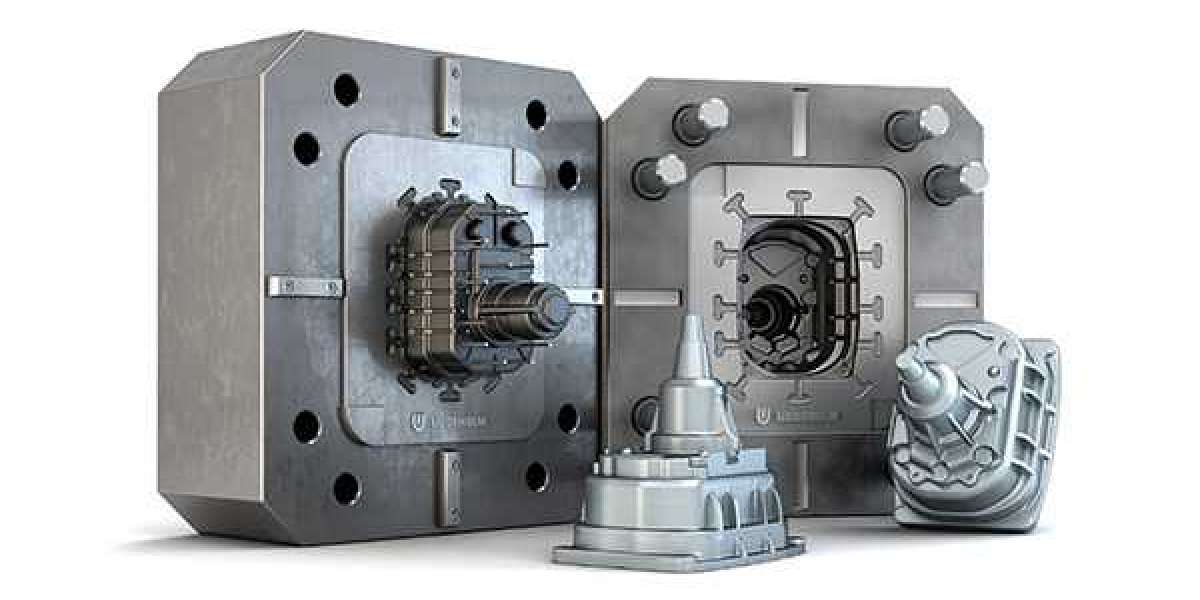

Because of the relentless march of science and technology forward, many traditional resources and tools are now considered to be obsolete. As a direct consequence of this, the resources and tools at our disposal are unable to fulfill the requirements of the population in the same way that they were able to in the past. You must not be familiar with the idea of die casting zinc alloy because you make it sound as if the idea has never occurred to you before. This suggests that you are not familiar with the concept. This indicates that you do not have a good understanding of the concept. As a result of this, we are in a position to fulfill the necessities of each and every one of our clients. In order to accomplish what needs to be done with a craft of this level, it is necessary to have the knowledge and experience of trained professionals who are experts in their respective fields. Before beginning the process, it is necessary to make sure that these are prepared. If the products that we manufacture are not of a high quality, it will be impossible for us to increase our sales and establish a powerful position in the market.

Those two goals are mutually exclusive. As a direct result of this, we need to increase the level of expertise that we have in all matters pertaining to production. In addition to this, the degree to which we have mechanized our operational procedures within our company needs to be increased as well. This step is absolutely necessary in order to bring a fruitful and satisfying conclusion to the process that has been zinc die casting products going on so far. If we want our products to have a higher degree of smoothness, we will need to use specialized equipment and an improved polishing method. Both of these things are going to be necessary for us to achieve our goal. These two things are going to be necessary in some capacity. If we want to be successful in achieving our goal, it is going to be absolutely necessary for both of these components to be in place. After we have finished this phase, we will move on to the next one, which will require us to carry out some additional processing in order to produce primary samples. In order to do this, we will move on only after we have finished the current phase.

In the course of this processing, specialized machinery will be utilized to treat the products in a variety of ways, including electroplating, baking paint, powder spraying, and so on and so forth. Each of these processes will be performed on the products in turn. These procedures will be carried out on the products in their respective distinctive manners, one after the other. As a result of these improvements, it will be able to have an overall longer life span. The implementation of these improvements is only going to be feasible under the following conditions:That we have made it this far through the procedure to the point where we are at the moment is a very significant accomplishment, and it is one that we should be very proud of. It is possible to draw this conclusion from the fact that there are stringent requirements that must be satisfied.