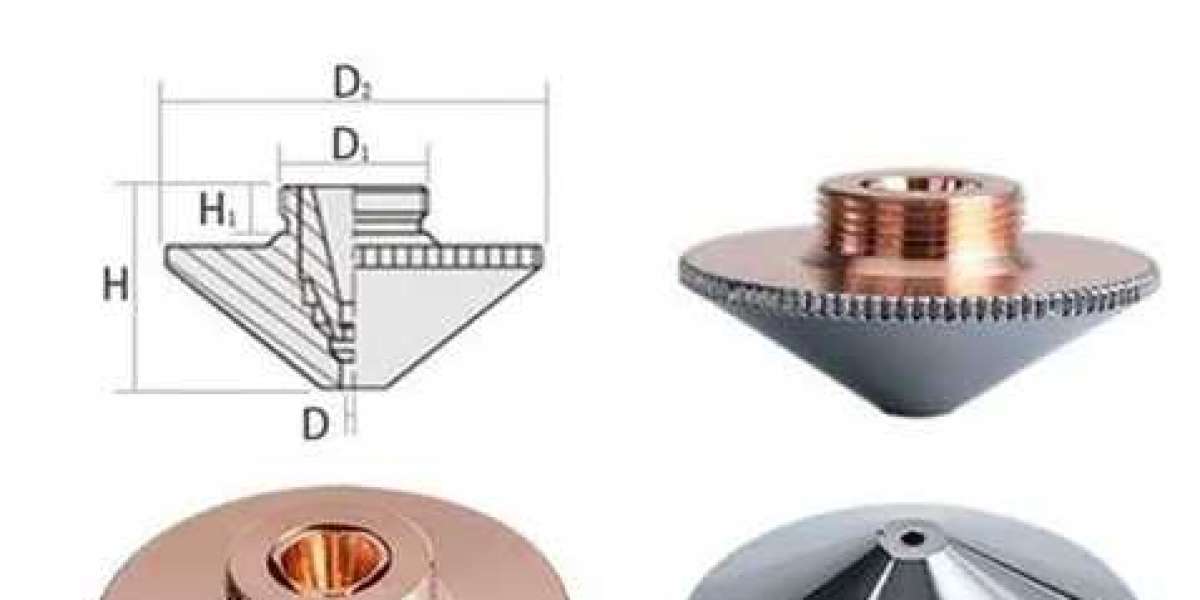

Fiber Laser Spares is the best supplier in India. Fiber Laser Spares is supply single/double nozzle, Raytools, WXS, Precitec.The fiber laser nozzle functions in the laser cutting machine, during the laser cutting process, the laser head nozzle collects the capacitance signal and transmits it to the signal processor through the ceramic ring, so that the distance to the laser head is proportional to the cutting process.

Can be held up to the workpiece during the laser cutting machine, and guides the gas to cut the workpiece smoothly, and by high pressure on the laser nozzle outlet attachment, accelerates the cutting speed, removes slag, and protects the lens inside the laser head.

.jpg)

Nozzle Size Selection

The diameter of the nozzle determines the size of the gas flow in the incision, the gas diffusion area and the gas flow rate, which affect the removal of the melt and the stability of the cutting.

If the airflow in the incision increases, it indicates that the movement is fast and the position of the workpiece in the airflow is appropriate. The stronger the ability of the spray to remove melts, the higher the laser power used and the fiber laser Ospri/WSX nozzle is sized according to the thickness of the metal sheet cut.

In theory, the thicker the plate, the greater the use of the nozzle, the higher the setting pressure of the proportional valve, the higher the flow rate and the pressure to ensure the normal section effect.